Down Ampney Grid Support Battery Project

Project Overview

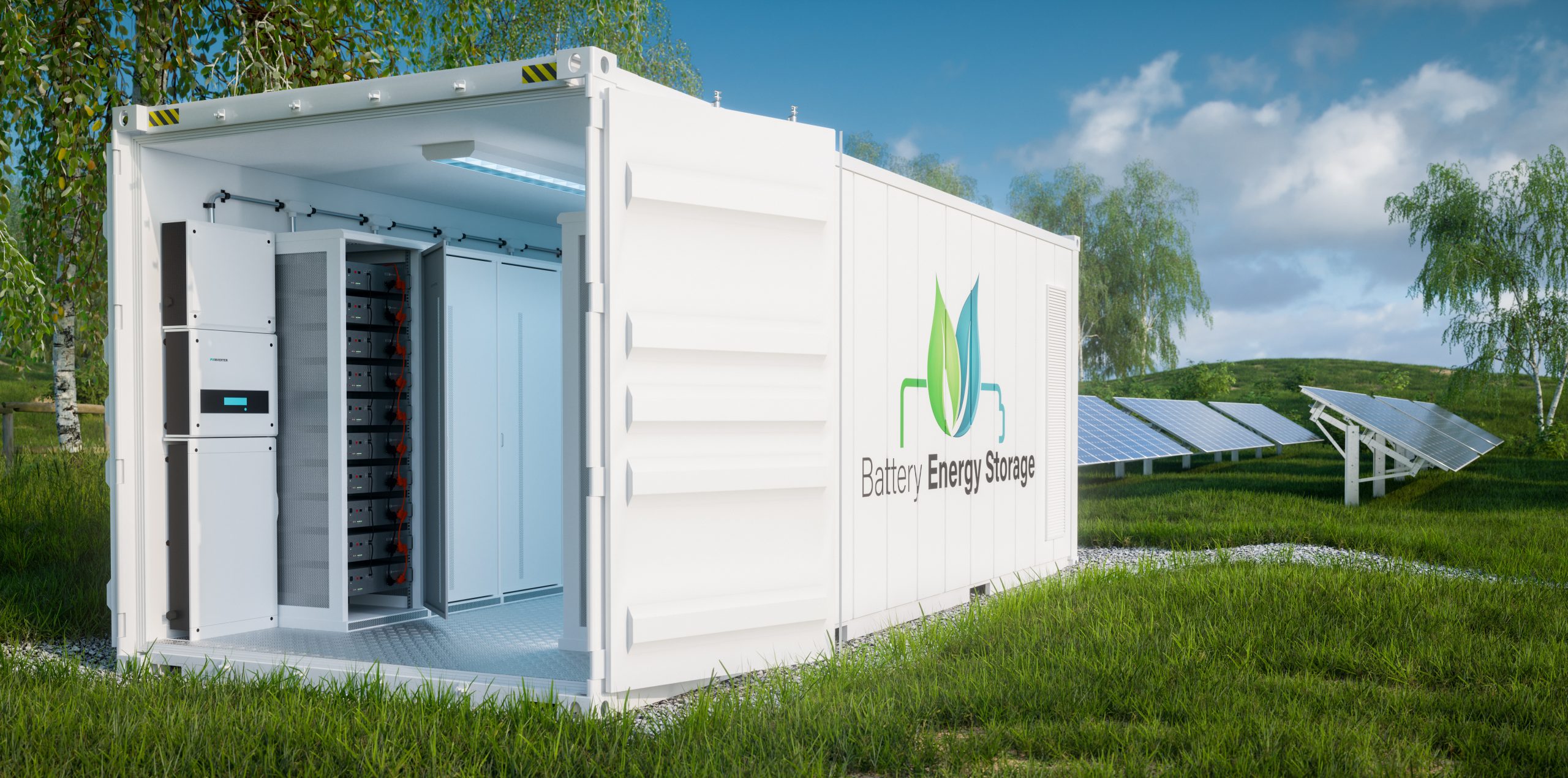

Down Ampney required a practical route to support a high electrical demand profile while working within a constrained grid import capacity. REDUCE LIMITED developed a battery-led solution to enable site operations at up to approximately 3.5MW load with only approximately 750kW available from the grid, using a containerised BESS configured for LV output and stepped up to 11kV for connection into the site network

Objectives

Key Details

Down Ampney required a practical, high-integrity energy solution to enable high-power site operations despite a constrained grid import capacity. The objectives for the project were to:

-

Enable operation of site loads up to approximately 3.5MW while limited to approximately 750kW of grid import capacity.

-

Specify a battery energy storage solution capable of supplying the shortfall during peak demand periods, with appropriate LV-to-11kV electrical interface design.

-

Provide a modular, containerised system architecture to support maintainability, staged delivery, and future adaptability.

-

Simplify controls and operational management by adopting a platform with integrated energy management functionality, reducing the need for separate EMS procurement and interfaces.

-

Develop an integration approach suitable for a medium-voltage (11kV) site network, with clear provision for compliant protection, metering, commissioning, and operational testing.

-

Deliver a technically robust route that reduces reliance on immediate upstream network reinforcement, improving programme certainty and operational resilience.

Implementation

Down Ampney required a practical, high-integrity energy solution to enable high-power site operations despite a constrained grid import capacity. The objectives for the project were to:

-

Enable operation of site loads up to approximately 3.5MW while limited to approximately 750kW of grid import capacity.

-

Specify a battery energy storage solution capable of supplying the shortfall during peak demand periods, with appropriate LV-to-11kV electrical interface design.

-

Provide a modular, containerised system architecture to support maintainability, staged delivery, and future adaptability.

-

Simplify controls and operational management by adopting a platform with integrated energy management functionality, reducing the need for separate EMS procurement and interfaces.

-

Develop an integration approach suitable for a medium-voltage (11kV) site network, with clear provision for compliant protection, metering, commissioning, and operational testing.

-

Deliver a technically robust route that reduces reliance on immediate upstream network reinforcement, improving programme certainty and operational resilience.

Key Details

Energy needs and costs

Down Ampney’s site load can peak at around 3.5MW, while available grid import is limited to around 750kW, creating both an operational constraint and a cost challenge because electricity is typically more expensive during weekday peak periods under time-of-use (half-hourly) tariffs.

How the battery delivers savings

A 3MW / 7MWh BESS reduces energy costs by changing when electricity is bought from the grid:

-

It charges during cheaper off-peak periods and discharges during expensive peak periods, cutting the volume of peak-priced electricity purchased (tariff arbitrage).

-

It supplies peak demand locally, reducing the site’s peak grid import and therefore exposure to peak-driven network and capacity charges (peak shaving).

-

It fills the gap between the grid limit and site demand during high-load periods, supporting operations without immediate grid reinforcement (constraint management).

Batteries as project enablers

The battery energy storage system is a key enabler for the quarry site’s development because it provides the additional power required to operate high-demand plant and equipment despite the limited grid import capacity available today. Without this approach, the project would be dependent on upstream network reinforcement and would likely have to wait until 2036 or later for sufficient grid capacity to become available, delaying commercial operations and investment. By bridging the gap between the site’s peak load and the constrained grid supply, the battery allows the business to proceed now, with a practical, engineered pathway that supports growth while longer-term grid upgrades remain outside the site’s direct control.

Future solar development

The battery solution also materially improves the site’s headroom for future solar expansion because the system architecture enables additional PV generation to be connected on the DC side and managed within the battery’s control envelope. While the current proposal could deliver around 1.4MW of solar, the DC-coupled arrangement means the site can scale on-site generation significantly further – up to approximately 6MW – without needing to request additional export capacity from the DNO, because the battery can absorb surplus generation and regulate what is presented to the grid connection. In effect, the battery turns a potentially export-limited PV project into a flexible, expandable on-site generation platform, supporting phased development while keeping the grid interface stable and compliant.

Environmental Benefits

Charging the batteries with low-carbon electricity delivers tangible carbon savings and wider environmental benefits by reducing the site’s reliance on higher-carbon grid electricity during peak periods. In the near term, the battery can be charged overnight when the grid typically has a lower carbon intensity, then discharged during daytime operating periods to displace higher-carbon, higher-cost consumption. As the on-site solar array is expanded, a growing proportion of battery charging can be supplied directly by renewable generation, maximising on-site utilisation of clean electricity and minimising curtailment. This approach reduces operational CO2 emissions, supports a more efficient use of renewable energy, and helps decarbonise high-demand industrial activity without waiting for major grid reinforcement.

Conclusion

The Down Ampney battery project provides a practical, engineered pathway for high-demand operations to proceed despite a severely constrained grid import capacity. By deploying an approximately 3MW / 7MWh BESS with an 11kV interface, the site can support peak loads that would otherwise be unachievable without major network reinforcement, enabling the quarry development to move forward now rather than waiting until 2036 or later for additional grid capacity. Beyond immediate operational enablement, the battery establishes a scalable energy platform that unlocks future solar expansion – from an initial proposal of around 1.4MW to as much as approximately 6MW of on-site generation through DC coupling – while maintaining control of the grid interface and avoiding unnecessary DNO export applications. The system also delivers long-term commercial and environmental value by shifting energy purchase to lower-cost, lower-carbon periods and, over time, increasing the proportion of operations powered by on-site renewable generation.